- Call:

- +38 067 898 85 89

About company

DAVIKA

The DAVIKA company was founded in 2018 in Ukraine, Kharkiv.

The initial and main idea when creating the company was the development of new products.

Working on a number of projects required finding outsourcing services for milling a large quantities stainless steel and aluminium prototypes.

Therefore, in 2020, we built our DAVIKA Workshop and equipped it with a new OKUMA milling machine, the best metal cutting tools and Kaiser compressor equipment.

Today, the main activity of the DAVIKA is high-precision metal milling services.

NEW LEVEL

OF CNC MILLING

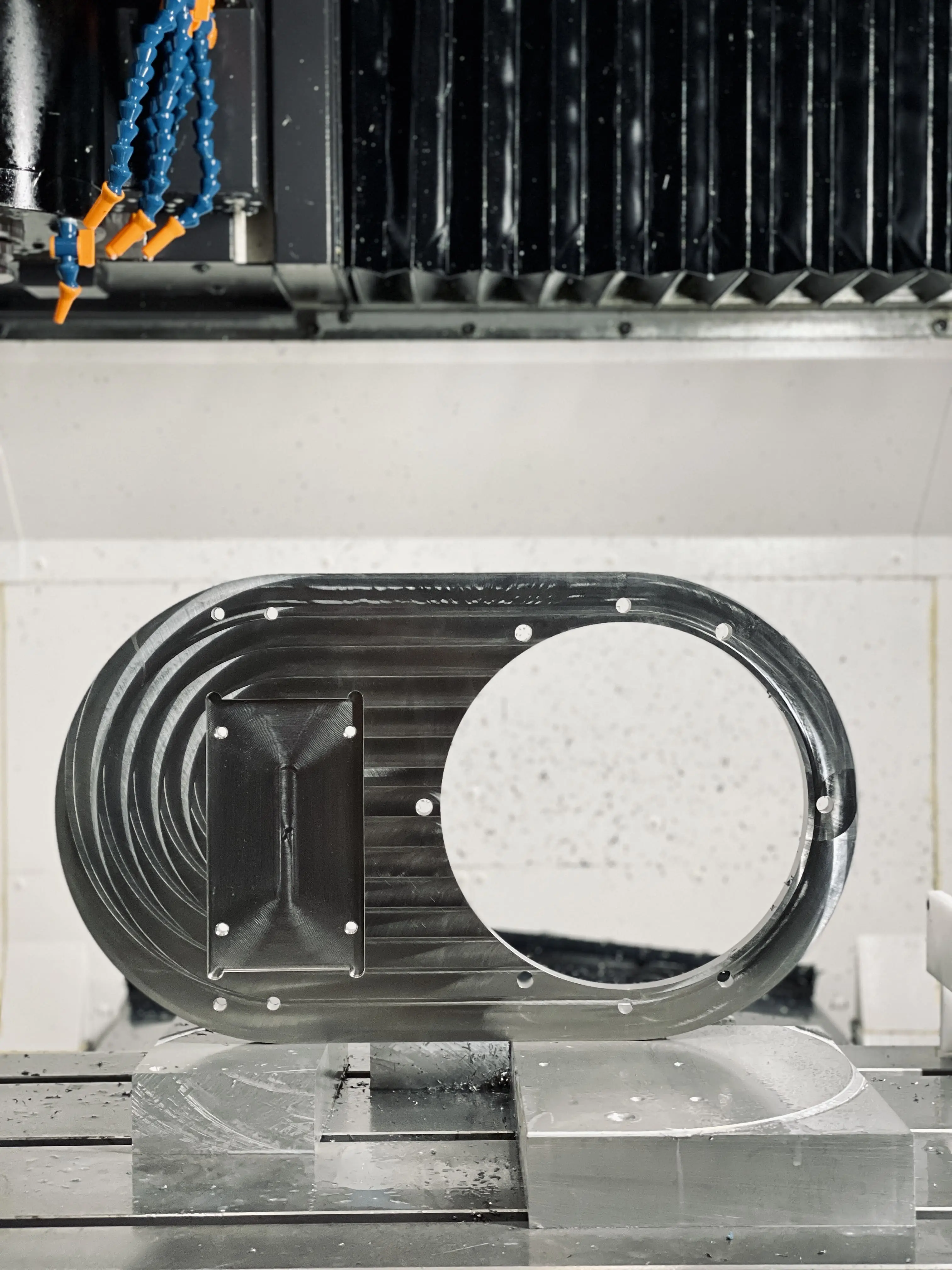

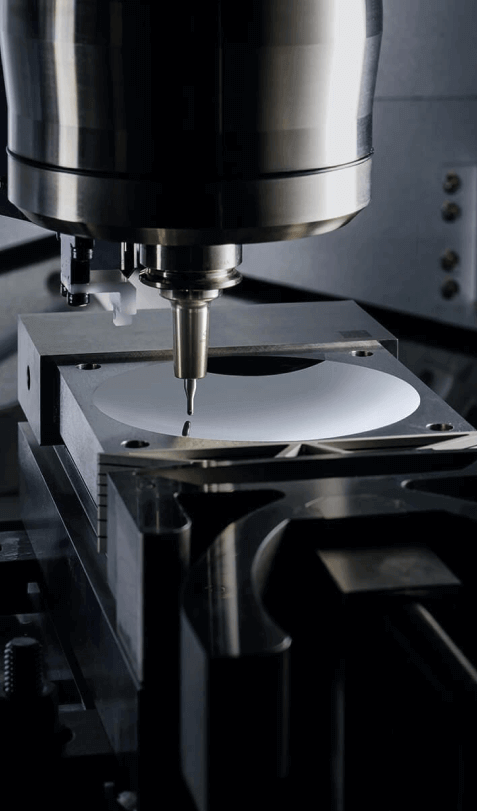

In ours Workshop we are using high precision milling machine, best cutting tools, precision vices and in-process quality control. Whatever types of tight-tolerance parts we come across, our engineers are able to pick the most suitable milling strategy for making them.

We understand how to make precision parts.

NEW AND MODERN

EQUIPMENT

POSSIBILITIES OF HIGH-PRECISION METAL MILLING

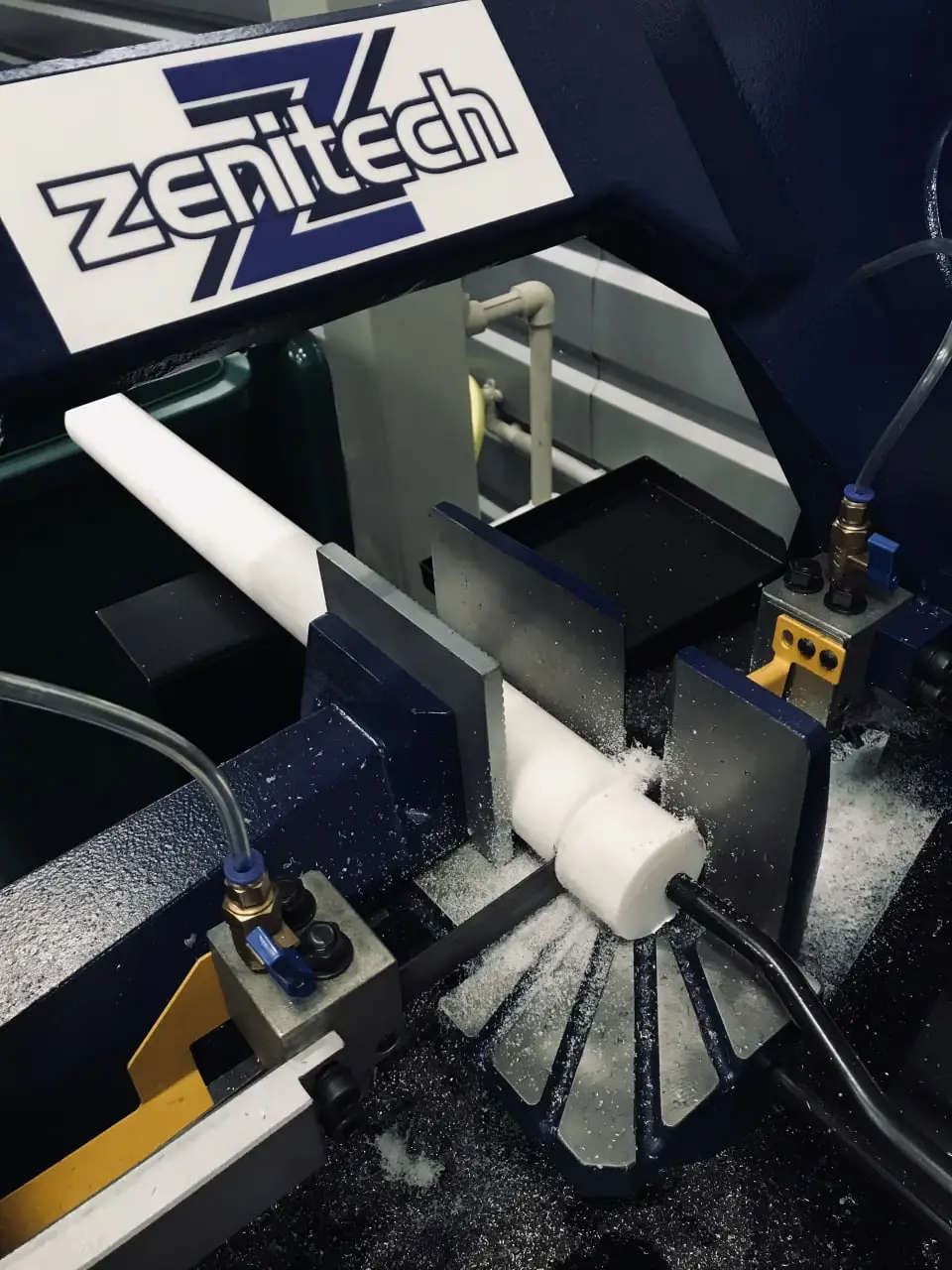

We provide milling services for stainless steel, aluminium, other ferrous and non-ferrous metals, as well as various non-metallic materials

- Machining Volume

- 762 × 460 × 460 mm

- Position accuracy

- ±0,004 mm

- Repeatability

- ±0,0015 mm

MILLING

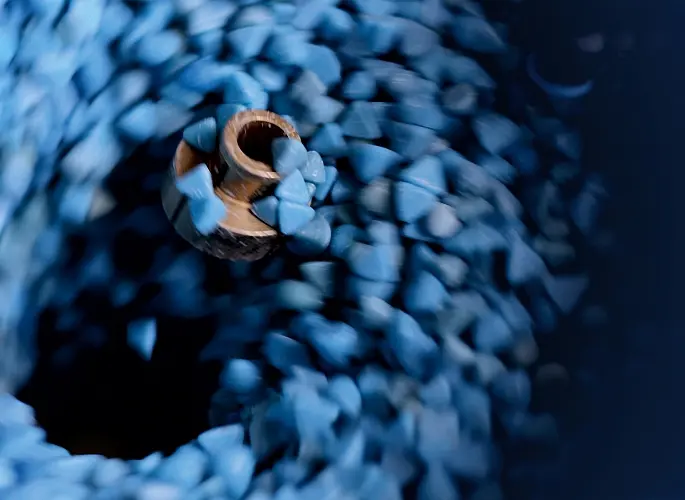

Metal milling is one of the most common types of metal machining.

Our milling machine is extremely rigid, equipped with a 15,000 rpm motor spindle, high pressure through-spindle coolant, automatic tool changer for 32 tools, which optimizes the process to reduce costs and shorten production cycle times.

SURFACE FINISHING

We use the AVALON TE18 disc finishing machine for surfaces finishing after milling.

This machine is designed for processing small parts and is also compatible with dry and wet polishing methods and can achieve an almost mirror-like surface.

Gallery